Molybdenum Foil in UV Lamps

Construction of typical UV lamps

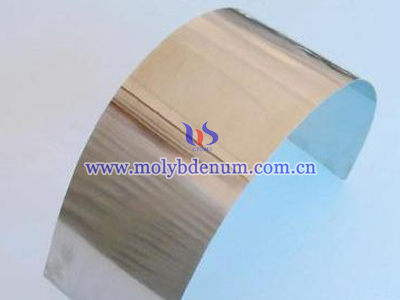

Molybdenum electrodes are used to make the electrical connection via a molybdenum foil seal, and this is terminated by a metal cap or ceramic base with wire leads.

Technical specifications of UV lamps

| Envelope: | High clarity vitreous silica (Quartz). |

| Electrodes: | Molybdenum rod, over wound with thorium coated, throated molybdenum wire, fused to molybdenum foil. |

| End Cap: | Manufactured from stainless steel, chrome-plated brass, or ceramic, dependent on lamp design. |

| Lengths Available: | From 6cm to over 300cm. |

| Power Available: | Up to 500 Watts per cm (1270 Watts per Inch). |

UV curing lamps

UV curing lamps are made and designed from high-clarity, vitreous silica, normally referred to as quartz. The electrode components are also manufactured from the highest quality materials ensuring long and reliable lamp life. Electrically, the lamp may operate for many thousands of hours though, at an earlier stage it will have ceased to emit adequate UV light. Therefore, molybdenum foil is really a electrode, which can make lamp use longer.

It is worthy of being mentioned that our company offer qualified molybdenum foil, whose standard is matched ASTM B386.